Cannula Processing Specialists

With our manufacturing process specialized for cannulas, we create designs using flexible thinking based on our customers’ needs in order to offer high-quality cannula products with advanced manufacturing technology

●In-House Developed Equipment

All of our major equipment is developed in-house, enabling us to provide high-accuracy, low-cost products that our competitors cannot match.

●Flexible Production System

We provide products through a flexible system enabling us to handle small lots to mass production with fast delivery times.

●Creation of New Value

Valuing flexible thinking, we create valuable products that meet our customers’ needs.

●Made to Order

We design and produce products to fit our customers’ needs.

Processing Technology

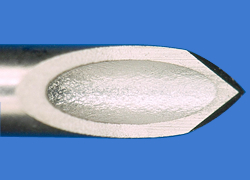

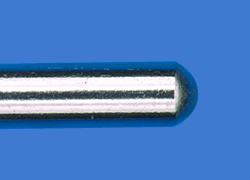

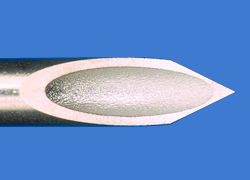

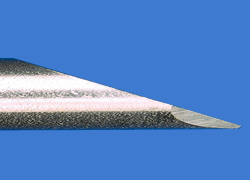

Lancet Point

|

【Features】

Outer diameter Ø0.18 to 12.0mm : total processing length is negotiable. |

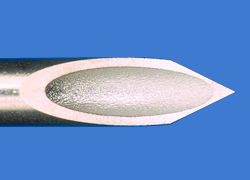

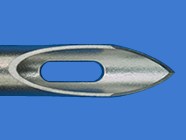

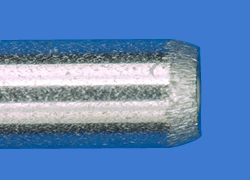

Semi-lancet Point

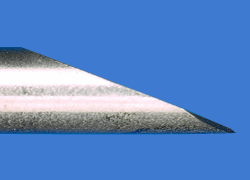

Back Cut Point

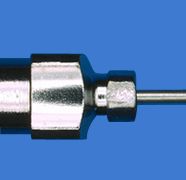

【Features】

Outer diameter Ø0.35 to 0.80mm : we can offer a wide array of processing including full length, hole diameters, positioning, final processing, etc. |

|

|

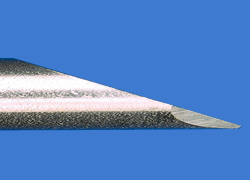

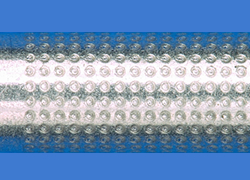

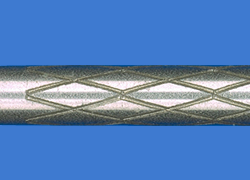

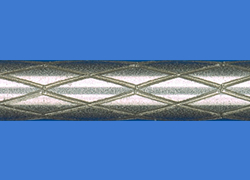

Electrolytic grinding

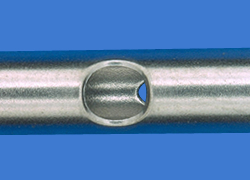

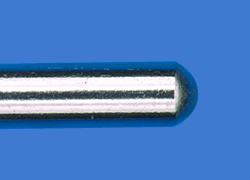

Closed Tip

|

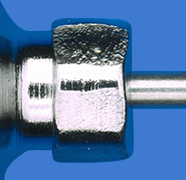

【Features】

The tips are processed to be smooth after welding. They can be processed in various ways, including shapes, hole diameters, positioning, etc. |

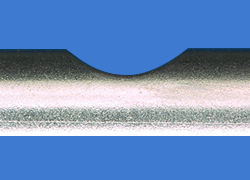

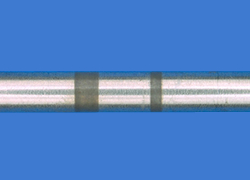

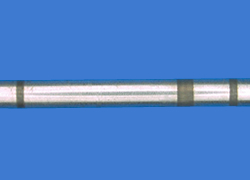

Clamp

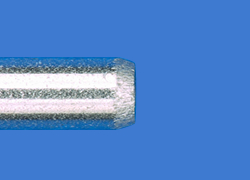

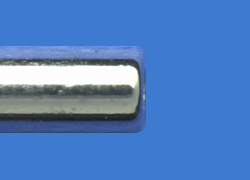

Rounded Ends

Before rounding |

After rounded |

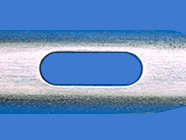

Back-Eye

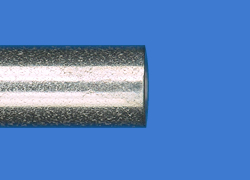

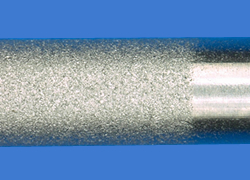

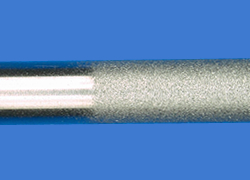

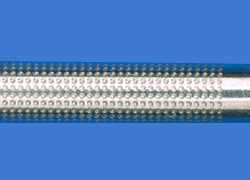

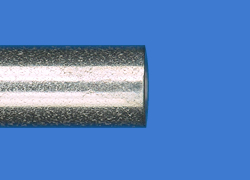

Gritblast

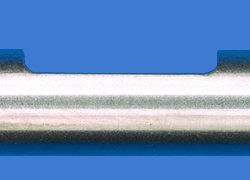

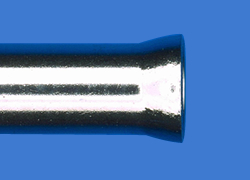

Flare

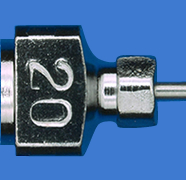

Etch-Marks

Laser marking

Bent Tip

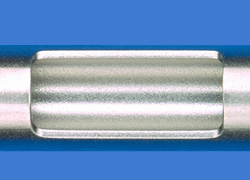

Swedging

Bent

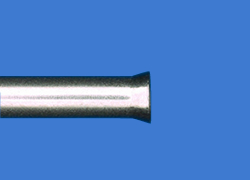

Chamfer end

Internal Round Off