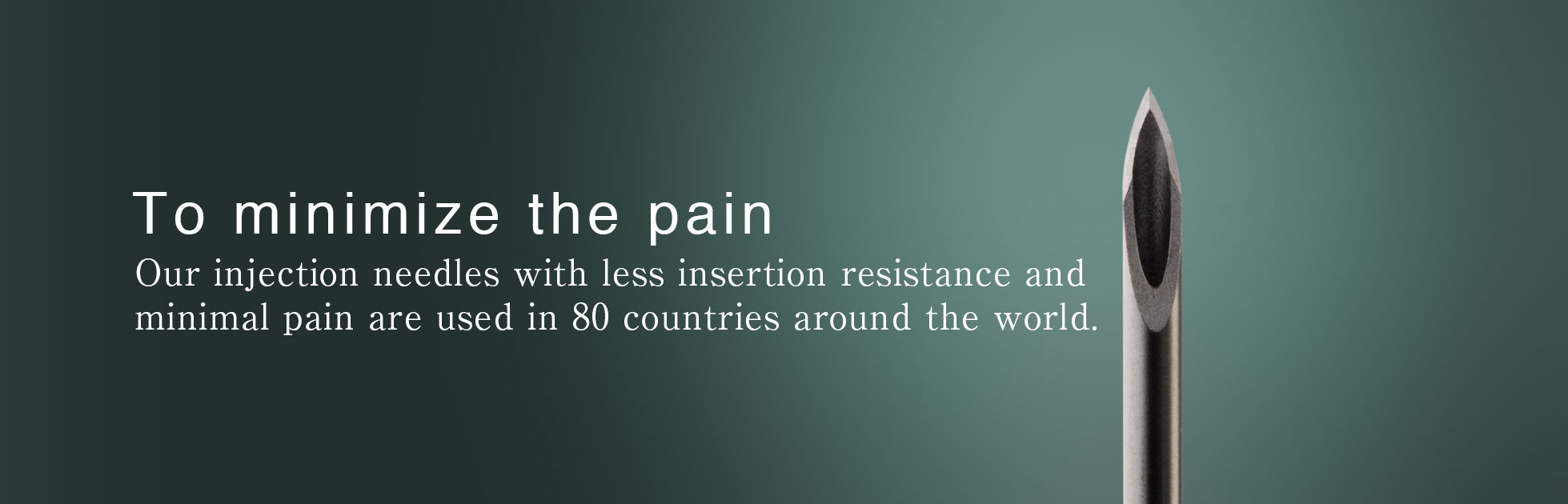

Injection Needle Components

Cannulas

|

The core component of an injection needle is the cannula. We offer our own injection needle cannulas highly-evaluated in the hospital, dental, aesthetic, and ophthalmology fields. Applications are not limited to medical use, and are compatible with a wide range of applications. ● 14G (2.10) to 33G (0.20), lengths of 12 mm to 500 mm available. ●Our international quality products are manufactured under our strict quality control system. |

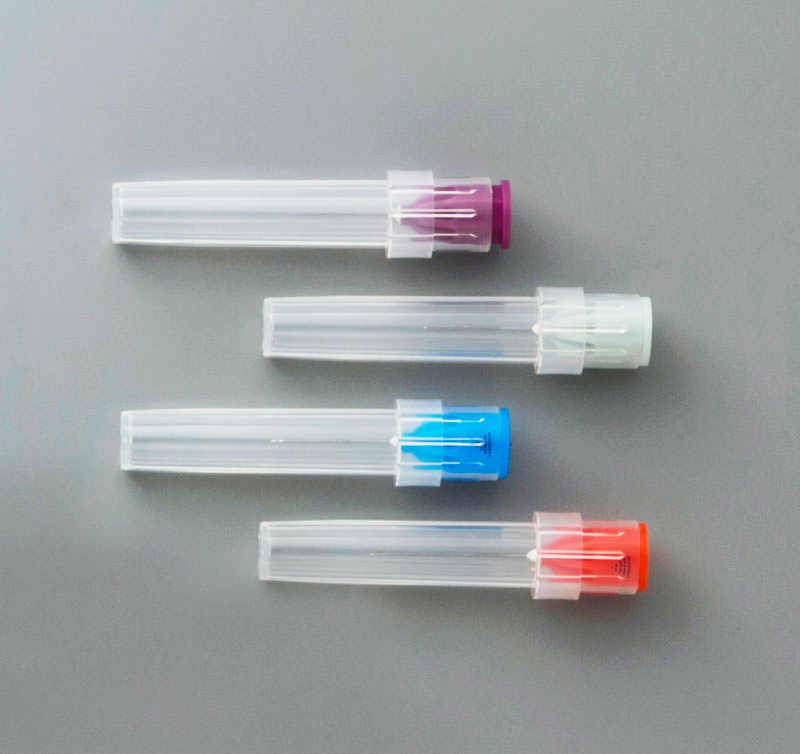

Hubs and Caps

|

We supply hubs and caps for use in hospital, dental, aesthetic, and ophthalmology fields which are sold as finished products of Misawa Medical Industry.

We are able to respond flexibly to customer requirements for hub color. ●Hub color can be specified. ●Various sizes and injection needle shapes are available. |

Plastic Products

Syringes

|

In addition to injection needle hubs and caps, we also manufacture syringes. Syringes manufactured under our system of international standards for quality control have received the same high praise as our injection needles from customers around the world. |

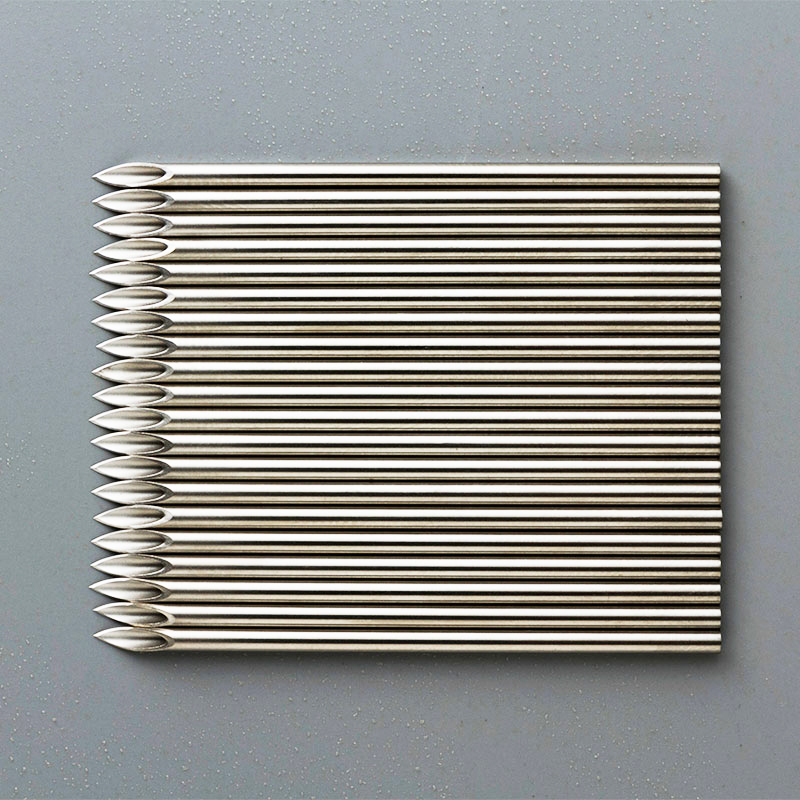

Stainless Steel Pipe

Stainless Steel Pipe

|

Stainless Steel Pipe

All stainless steel pipe from our injection needle manufacturing process is tested for cracking.

Pipe dimensions specified by the customer can be accommodated to ISO Standard pipe dimensions.

We can also provide pipe according to various hardness requirements. ●We are able to accommodate sizes from 33G (outside diameter 0.20 mm, wall thickness 0.06 mm) to 14G (outside diameter 2.10 mm, wall thickness 0.2 mm). ●Pipe dimensions specified by the customer can be accommodated to ISO Standard pipe dimensions. |

Stainless Steel Cut Tube

|

Stainless Steel Cut Tube

All tested stainless steel pipe from our injection needle manufacturing process is available in cut lengths.

While we use stainless steel tube for injection needles, it is also used in a range of other applications such as endoscopes.

Pipe dimensions specified by the customer can be accommodated to ISO Standard pipe dimensions. ●We are able to accommodate sizes from 33G (outside diameter 0.20 mm, wall thickness 0.06 mm) to 14G (outside diameter 2.10 mm, wall thickness 0.2 mm). ●Pipe dimensions specified by the customer can be accommodated to ISO Standard pipe dimensions. ● A laser marking service for cut pipe is also available. |

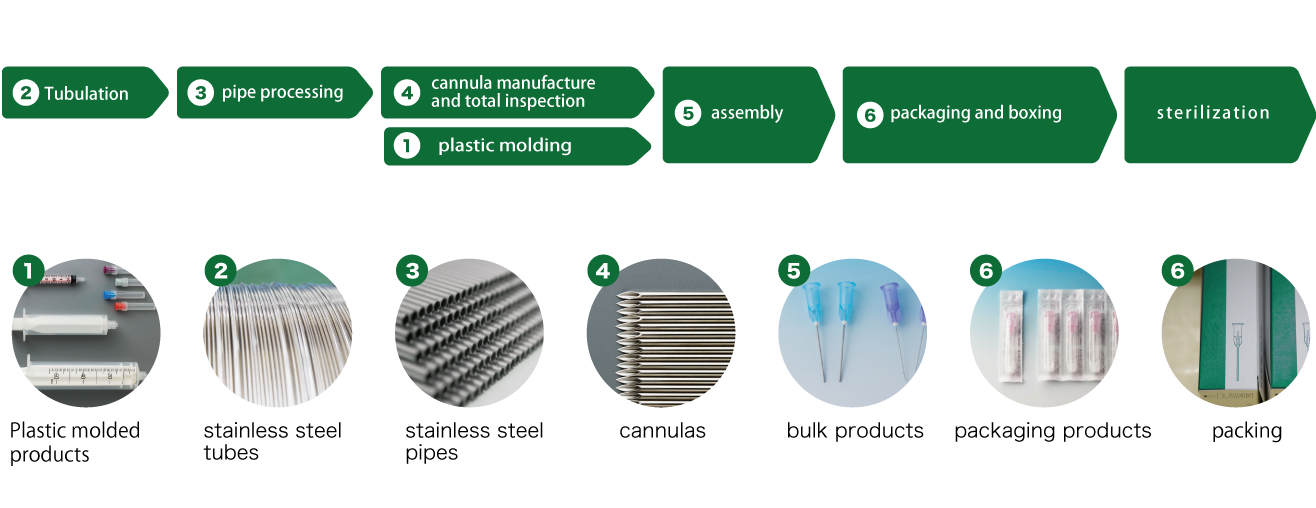

Services

Assembly Service

|

All assembly work is performed in clean rooms. We supply, assemble, apply coatings, package, and box injection needle components such as cannulas and hubs.

We also carry out acceptance inspections and component assembly under international quality control standards. ●We are able to produce OEM products of injection needles using cannulas from other manufacturers, and customer-supplied components. ●We are able to respond flexibly to a wide range of customer needs. |

Sterilizing Service

|

We provide sterilization services to customers needing only sterilization. We are also able to sterilize other products besides injection needles. We provide reasonably-priced sterilization with sterilization equipment compatible with international standards. |